Over time as the technology has improved, 3D printers have gotten much cheaper. Much like any other sector of technology, with the advent of new methods of transferring designs from concept to reality in three dimensions, and increased production of these revolutionary machines, the prices continue to drop significantly. Sooner or later, you may find yourself owning one.

How can you decide between FDM 3D printers and resin printers? There are a couple of factors that separate the two. After analyzing these differences you will be able to pick the best 3D printer to suit your needs.

How do they work?

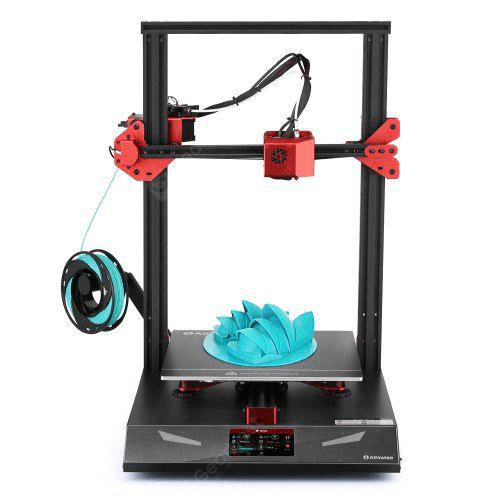

First of all, we need to know the fundamental differences between the two printers. As their name implies, FDM or filament printers print by melting the filament; a thin strand of polymeric material, and basically “drawing” the 3D object layer by layer using the filament. This is the basic and most common technique used for small to medium scale 3D printing.

Resin printing is different in the sense that although it still produces objects layer by layer, It uses UV light projected at specific points in a pool of resin to harden it into it’s required shape. This process is called curing. After this, the printed object is then lifted out of the pool of resin.

What else do you need to know to make a decision? Let’s see three major factors that may determine which is best for you.

- Cost: Easily one of the biggest determining factors when choosing a 3D printer will be how much you’re ready to spend.

FDM printers are also cheaper to operate in the long run. A spool of filament used by FDM printers usually goes for about $25. The parts, which need only be replaced once in a while, also happen to be easily accessible and cheap to purchase. Nozzles and extruders are quite inexpensive.

Resin printers, however, require relatively frequent resin tank changes, as well as the regular resin fill up. A resin tank goes for about $40. Resin sells at about $80 per liter. This may be something to consider especially when you are an entry-level 3D enthusiast.

- Quality: The quality of the final product of both printers also sets them apart. FDM printers are known for dealing with several quality issues such as shrinkage and at times, warped layers. Generally, however, the quality of a model from a good FDM printer is still a beauty to look at.

Resin printers print with superior quality, though, as using a laser or a projector allows for even more detailed printing, and this results in a finish distinguishable from that of FDM printers. There is a difference in quality, but it isn’t extreme.

- Ease of use: Regardless of which printer you use, you’ll need to master 3D software, have a level printing bed, and also load your material properly. FDM prints tend to be easier to prepare and remove from the print bed, and are also easy when it comes to post-processing.

Resin printers are more complex to deal with and require more intricate post-processing. The same can be the case with an FDM model, but this just depends on the quality of finish you want on your model.

Nothing beats FDM printers for beginners and intermediate 3D designers and it remains one of the easiest and cheapest 3D printers to run even for advanced designers. FDM 3D printing is a good choice. But if you are concerned with very intricate details and need a model that’s close to perfection, a resin printer is the best way to go. Either way, you’ll get a lot out of these printers, that’s for sure.