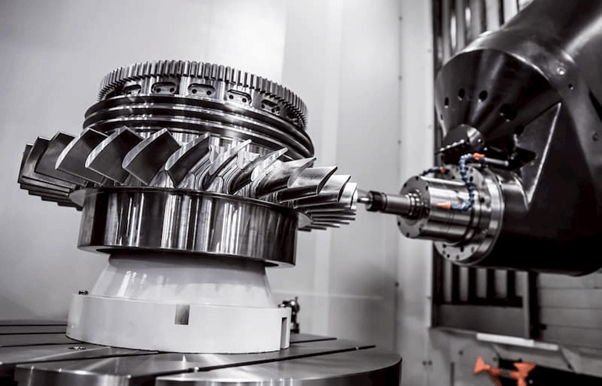

CNC plastic-type machining is prominent for using some of the most modern computer methods and numerical control techniques. For example, in the process of milling aluminum, sophisticated machines get used, which are vividly automated but are all controlled by programmed computers. Typically, the lack of various molds cut down the cost as well as time while making it possible for professionals to obtain certain identical parts created from top-notch material. Hence, such fact ascertains that CNC machining is the right method for different items productions, for instance, visual as well as functional tests. In this article, we talk about CNC Milling aluminum processes.

CNC Aluminum Machining History

CNC aluminum machining refers to a technique or machining that was largely developed around 18th century using a turning metal frame that was invented around the 1750s. It happened to be the primary product of a series of various machines that aimed to create precise operating operations that are achievable by the use of top-notch handcrafted techniques. Initially, this largely marked the outset of industrialization.

Handcrafted techniques primarily operate CNC aluminum machining, and it’s the technique that marked the outset of industrialization.

Features of aluminum material

Aluminum is not just soft but malleable and tractable. It has a silver-like appearance that looks grey. Its appearance intensely depends on the rough look of the surface. Aluminum lacks any form of magnetic properties.

It is also non-flammable. Typically, the metal will melt at about 640 degrees because it is light and comes with a density of about 2.68. Other than that, it is also an excellent conductor of electricity even though it is actually not similar to copper on some cross-sectional regions. The material is widely utilized in the CNC automotive sectors such as Aerospace and ATV.

Aluminum grade

Sometimes, the definitive choice of aluminum grade and type you want to use highly depends on the machining projects you have, which will allow you to rank every grade according to the character it has. This should be from the most crucial one to the least. In so doing, you are in a position to select the aluminum of a specified property coupled with the shape you would go for, and that suits your needs.

Essentials of aluminum grade

To understand the basics of aluminum machining, you need to have a detailed comprehension of the grades of metals involved. Here are some of the well-known aluminum grades:

- Aluminum 6061: this is a trusted aluminum grade with superb mechanical properties. It also comes with excellent weldability. The material’s topical properties make it an extruded grade because it comes with some element of sturdy nature coupled with corrosion resistance on any harsh condition.

- Aluminum 7075: this is a prominent type of metal, although 6061 is more prominent. The grade is clearly known for its fatigue strength. But, it is not really suitable for welding but costly. For that reason, it is ideal for tough parts, including rock climbing kits, as well as aircraft wings.

- Aluminum 2024: this is an alloy that is predominantly used in the aerospace industry because of its mechanical properties. It also has a high temperature and is corrosion resistant.

Final Thoughts

Aluminum machined prototypes are often produced according to different alloys. 6061-T6 is one of the most used aluminum since it caters to electronics and transportation in the aerospace.