Computer Numerical Control (CNC) machining is pivotal in the manufacturing industry. CNC machining is unlike traditional machining that requires engineers to operate equipment such as vertical millers and shaping machines. Additionally, CNC machining is often used for low volume production and rapid prototyping. It has two major services; CNC milling and CNC turning service. Furthermore, CNC machining has proven beneficial in various industries. This post, therefore, aims to update you on the benefits of CNC machining.

Eight Merits of CNC machining

1. Safe operations

CNC machining allows for safe operations. Therefore, the number of accidents as a result of machining has considerably reduced. CNC machine operators work by operating behind a closed-transparent door or guard. Therefore, they get into minimal contact with the machine as much as possible.

2. Fewer errors

The CNC machining allows for less human contact with the machine; most of its services are computer-controlled. Computer operations are not like human operations. Humans are most likely to commit mistakes during the machining process. Therefore, the limitation of human interferences increases accuracy levels and reduces errors. Furthermore, the computer is programmed to work with a particular tolerance and requirements. It also has software that dictates how the machining process will go. Therefore, CNC machining has fewer errors. It also encourages fewer wastes.

3. Increased production speed

Due to computer control, processes are automated. Therefore, it provides room for quality manufacturing at high speeds.

4. Reliable

CNC machines are pretty reliable. They can work on holidays, daily and on weekends. The only time they can stop is during repair and maintenance. Therefore, the CNC machines do not require breaks or tires quickly. Thus, production is done efficiently and at a fast pace.

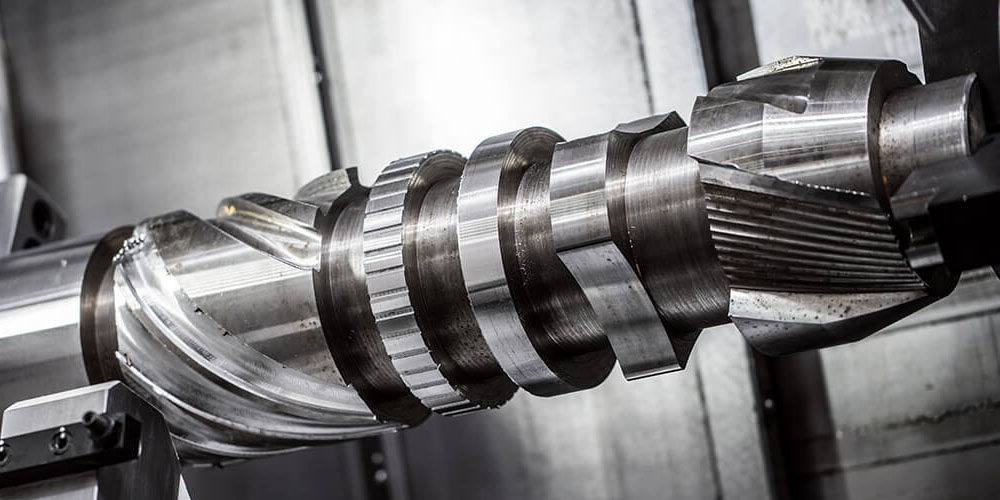

5. Production of complex shapes

CNC machining does not limit to the production of simple parts only; it manufactures complex shapes too. Its high precision rates ensure that the machine can produce intricate parts that other machining services, such as manual machining, cannot replicate. Furthermore, the engineer’s programming ensures that CNC machining is flexible.

6. Cost-effective

CNC machining is unlike traditional machining. The traditional machining required one operator for each machine. But CNC machining requires one operator to operate several machines at a go, reducing labor costs. Generally, labor costs add to the overall production costs. But the reduced costs of labor mean low production costs. Therefore, CNC machining is cost-effective.

7. Application in various industries

CNC machining is applied in various industries. That is, manufacturing, aerospace, automotive, medical, and so many more. Its application in several industries makes it an essential process. Furthermore, CNC machining is considered the future of production. It is constantly advancing; therefore, the processes are expected to be much simpler in the future.

8. Custom manufacturing

CNC machining allows for custom manufacturing. Therefore, the parts produced are relatively unique. Thus, customers can request the production of a part according to their needs.

Conclusion

CNC machining has advanced immensely from the last decade. More advancements are expected in the future. Additionally, CNC machining is crucial for the smooth running of the different sectors of the economy. The above are some of its top benefits.